LUYỆN KIM

Tư vấn công nghệ Nấu luyện lò Hồ quang, Lò Cảm ứng cho Gang, thép. Thiết bị thí nghiệm.

Thiết bị

Công nghệ

1. Luyện thép lò Hồ quang

2. Gang cầu

3. Thép hợp kim

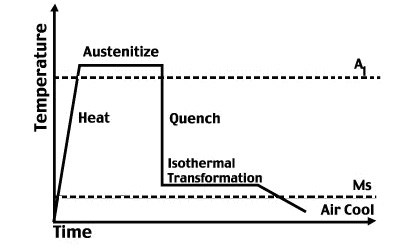

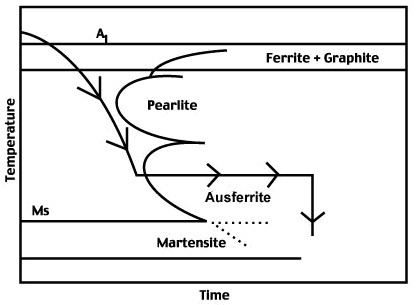

The Austempering Process

Austempered ductile iron is produced by heat-treating cast ductile iron to which small amounts of nickel, molybdenum, or copper have been added to improve hardenability. Specific properties are determined by the careful choice of heat treating parameters. Austempering involves the nucleation and growth of acicular ferrite within austenite, where carbon is rejected into the austenite. The resulting microstructure of acicular ferrite in carbon-enriched austenite is called ausferrite. Even rolex replica though austenite in austempered ductile iron is thermodynamically stable, it can undergo strain-induced transformation to martensite when locally stressed. The result is islands of hard martensite that enhance wear properties.

Advanced Cast Products uses salt baths for austenitizing, quenching, and austempering in order to achieve close dimensional control. Times and temperatures are tightly controlled throughout the entire process.

Steps in the ACP Austenitizing Process

1. Heat castings in a molten salt bath to austenitizing temperature.

2. Hold at austenitizing temperature to dissolve carbon in austenite.

3. Quench quickly to avoid pearlite.

4. Hold at austempering temperature in molten salt bath for isothermal transformation to ausferrite.

Consistent control of times and temperatures throughout the entire process

5. Initial austenitizing times and temperatures (1550° to 1700° F.) are controlled to ensure formation of fine grain austenite and uniform carbon content in the matrix. The precise temperature is grade dependant.

6. Quench time must be controlled within a few seconds, to avoid formation of pearlite around the carbon nodules, which would reduce mechanical properties. Quench temperatures (450° to 750° F.) must stay above the point of martensite formation (except for ASTM A 897 Grade 5).

7. In the austempering step which follows austenitizing, the temperature of the final salt bath must also be closely controlled. The austempering step is also precisely time-controlled, to avoid over- or under-processing. By the end of this step, the desired ADI ausferrite structure has developed.

Tin liên quan